Maintaining a world-class testing lab ensures top-quality aroma diffusers.

As a renowned manufacturer of aroma diffusers and fragrances, we take great pride in securing the quality and consistency of our products. That’s why we implement strict testing standards for raw materials and finished products, making sure they meet not only yours but international benchmarks.

Compared to ordinary pumps used in air diffusers, our air pumps produce low noise and require 70% less electricity while offering high efficiency and extended service life.

Made from corrosion-resistant parts, the atomizing head has a long service life and requires no replacement, saving on maintenance costs and providing peace of mind.

We know that the overall quality of our products starts with the material we use to make them. To ensure we only use the best raw materials, we carefully screen material suppliers and conduct routine inspections on all incoming materials.

The atomizer core is connected to an air pump and an oil bottle to check its mist generation capability. We weed out cores that produce no mist, weak output, or show inconsistencies.

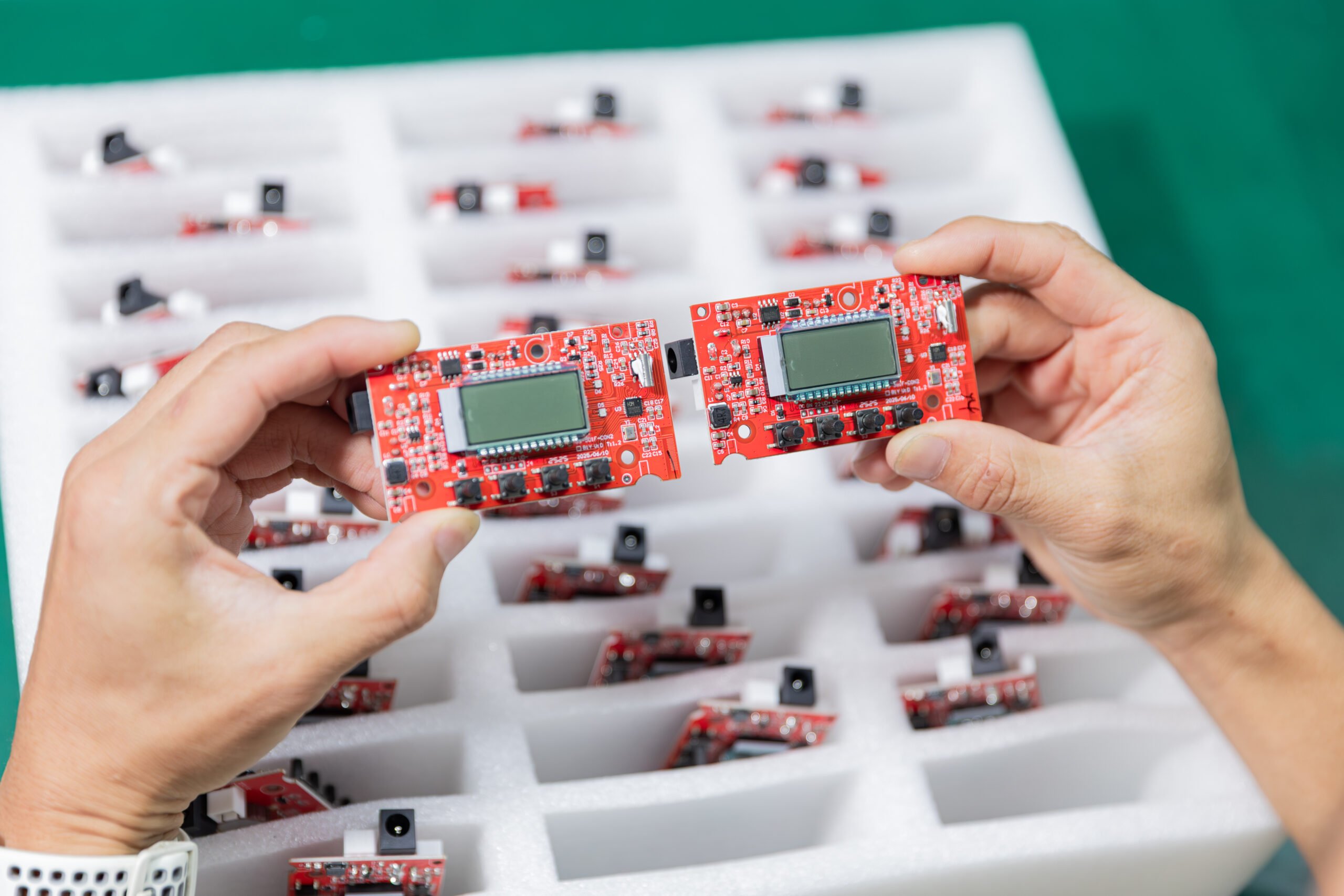

Thorough inspection of board components to ensure everything is in place and free of any issues. Solder joints should be flat and secure, with no false, missed, or wrong soldering, as well as no component damage and oxidation.

Using the mobile testing app, we check the PCB’s Bluetooth connection and other functional controls for optimal operation. We also check the run switch on the board to make sure it properly controls the air pump and fans.

Aside from routine inspections throughout the production process, we conduct a series of audits and tests at the end to verify the quality and consistency of our aroma diffusers. This ensures that all our products meet your standards and help build stronger brand recognition.

A product’s aesthetics is what a customer sees first, thus setting the stage for their overall experience. That’s why we pay close attention to how the aroma diffuser looks and feels, validating its pristine condition before leaving our warehouse.

Next, we check the performance of our custom aroma diffusers, reviewing every aspect to guarantee consistent functionality. Any issue with the machine’s functions will cause problems for your customers and your brand overall. Here’s what we look for while testing:

Another factor we look at is the stable and optimal performance of our aroma diffusers even after long hours of use. We expect our machines to work for extended periods, so they should be able to function consistently without a drop in quality.

We test the machines under accelerated aging conditions: 85°C, 85% relative humidity (RH), 72-hour continuous operation. Results are noted and used as a benchmark for all machines.

Lastly, we check how the aroma diffusers are packaged, along with the accessories they come with. We make sure everything needed is included in the package to avoid any customer discomfort.